The compost bin is used to convert the solid food waste into useful organic compost.

Greenrich Accelerated Micro-Composting Solution

Overview

Greenrich Grow proposes a state-of-the-art enhanced accelerated composting process which will drastically reduce the duration to 10 days compared to the 45 days conventional method.

How It Works?!

Composting is the natural process in which living organisms decompose organic matter into inorganic matter in the soil. The organisms feed on the organic material and through respiration generate the energy that they use for movement, growth, reproduction or stored energy. The organism excretes inorganic material that enriches the soil. When the organisms die, their bodies add to the organic matter in the compost pile.

The aerobic composting process starts with the formation of the first, mesophilic organisms (optimum growth temperature range = 10-40 °C) multiply rapidly on the readily available sugars and amino acids. They generate heat by their own metabolism and raise the temperature to a point where their own activities become suppressed.

Then a few thermophilic fungi and several thermophilic bacteria (optimum growth temperature range = 40 °C or more) continue the process, raising the temperature of the material to 65 °C or higher. This peak heating phase is important for the quality of the compost as the heat kills pathogens and weed seeds.

The active composting stage is followed by a curing stage (optimum growth temperature range = 10-40 °C. At this stage, another group of thermophilic fungi starts to grow. These fungi bring about a major phase of decomposition of waste materials.

Microbes stabilize the organic matter & aerobic oxidation produces CO2. Eventually, the temperature declines to ambient temperature. By the time composting is completed and the outlet is used as first grade compost.

Why Us!

Greenrich Group is committed to helping its clients reach their goals, to personalizing their experiences, to providing a sustainable environment, and to making a difference

Our strong sense of identification with client projects means that we are constantly striving to provide solutions, even for issues they aren’t yet aware of. To this end, we adopt a progressive approach to right technology and marketing techniques.

Greenrich Waste Management Solutions are ideal for transforming the organic waste into valuable resources like compost / biogas, waste to energy, waste to fuel / liquid fuel.

Greenrich’s diligent team of technical experts can customize from our extensive gamut of waste management offerings to suit your requirement.

We are the pioneer in offering a wide Range of Products catering to different Verticals like Households, Residential Apartments & Gated Communities, Institutions like Schools & Colleges, Offices, Hotels & Restaurants, Hospitals, Canteens & Factories, Malls & Halls, MSW treatment

Pit Composting

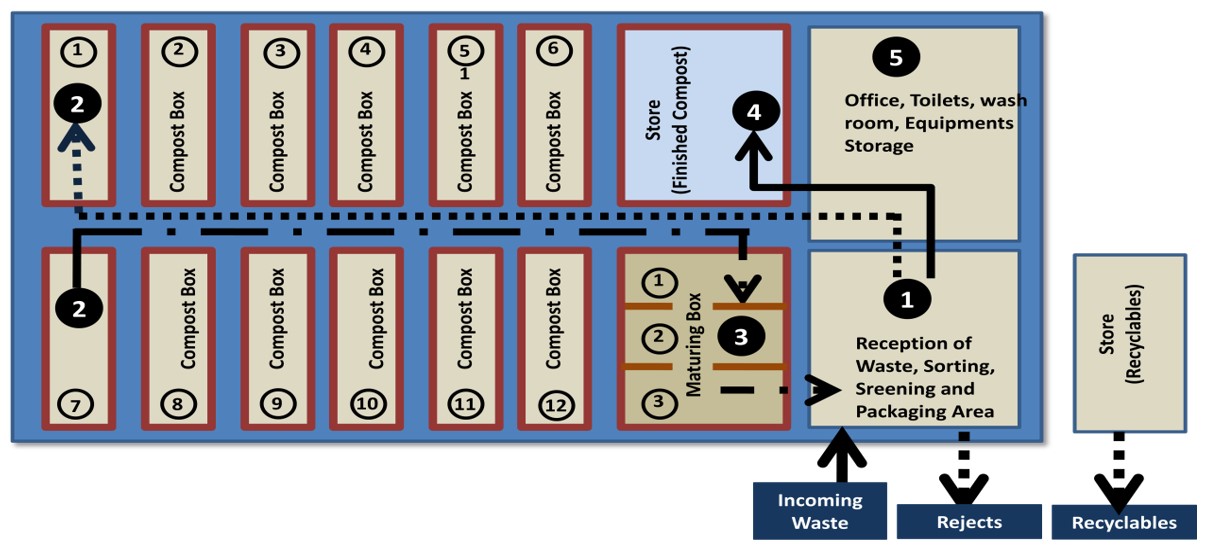

Greenrich Accelerated Micro-Composting Solution (GAMS) is a facility where significant portions of waste can be processed in a cost-effective way. GAMS looks at waste as a resource and mainly focuses on organic waste (fresh organic waste coming mainly from kitchens, restaurants, vegetable wholesale markets, parks and lawns) including meat & fish waste, etc.

GAMS’s capacity to process waste can vary from 2 to 20 tons per day, depending on the population and investment size. Considering an average waste generation rate of 0.4 kg/day, it can serve a population of 5,000-100,000. GAMSs can be established near a single community or near more than one community. This process reduces the waste volume by up to one-third. Based on the study, the compost conversion ratio from municipal waste varies between 15% and 25%, depending upon the type of waste composted, the technology used, and the composition of the waste. A significant portion (about 90%) of the collected waste can be processed and produce products with economic value, and the rest of the unusable inert material needs to be landfilled. All activities in GAMS are focused on promoting the 3Rs (reduce, reuse, recycle), cleaner technology, energy efficiency, and creates a profit-making enterprise.

Waste from households arriving at the composting plant is sorted into several fractions. The organic fraction enters the composting process. It is mixed with additives if necessary and piled into the composting system. The composting process has to be monitored by different parameters (temperature, moisture). Finally, the mature compost is screened and prepared for selling. Residues from sorting and screening are recycled or disposed.

Windrow Composting

Aerated (Turned) Windrow Composting

Composting takes place in the open air in large, elongated, uniform prism shaped ‘piles’ of waste known as windrows. The waste feedstock is mechanically shredded and placed into long windrows on a solid, non-permeable surface. Water may be added, depending on the moisture content of the waste.

To maintain an aerobic condition, the compost mixture must be periodically turned. This exposes the decomposing material to the air and keeps temperatures from getting too high (>170 °F). The windrows are turned regularly, either with a wheeled loader or by a specialist windrow turner machine (pulled along by a tractor / dedicated vehicle). The windrows are turned several times during the compost process. The minimum turning frequency varies from 2 to 10 days, depending on the type of mix, volume, and the ambient air temperature. As the compost ages, the frequency of turning can be reduced.

Aerated or turned windrow composting is best suited for large volumes of waste.

- The pile generates enough heat and maintains the temperature and allows oxygen flow to the windrow's core.

- Large volumes of diverse wastes such as yard trimmings and animal by-products such as fish and poultry wastes can be composted through this method.

- Turners drive through the windrow at a slow rate of forward movement. They have a steel drum with paddles that are rapidly turning. As the turner moves through the windrow, fresh air (oxygen) is injected into the compost by the drum/paddle assembly, and waste gases produced by bacterial decomposition are vented.

- Compost windrow turners work to mix oxygen and moisture into the compost, they also cool it down. Temperatures over 650C can damage or kill microorganisms that are key to producing high-quality compost.

- The Composting duration is 30 – 40 days. The fungal innoculum or microbes will be required to speed up the composting process thus avoiding bad odour and flies.

Key Benefits

- Best suited for large volumes of waste

- Open windrow composting is a relatively low capital waste treatment process

- Rapid drying with elevated temperatures.

- Drier product, resulting in easier product handling.

- Ability to handle high volumes of material.

- Good product stabilization.

- Saleable product

- Improves nutrient qualities

- Easy to implement and operate.

- Handles a large volume of material.